Our reusable products are made of a composite material called Bio-Compound. Compound comes from English and means “mixture” or “compound”. A composite material generally consists of two or more materials. When these are mixed together, a new material is created, which possesses favorable properties due to the combination. The mixing has optimized it, so to speak. The term Bio-Compound is not protected, so a variety of material combinations can fall under it.

Our reusable packaging

The special properties of our reusable containers

- Tested food safe

- Biobased from renewable raw materials

- Temperature resistant

- Dishwasher safe

- No melamine, no BPA

- Robust and break-proof

- Sustainable appearance and high-quality feel

- Developed and manufactured in Germany

- Lignocellulose from sustainable forestry

The advantages of Bio-Compound for plates, bowls, cups, and more

The material of the various reusable packaging for gastronomy and food service has many good properties. They are freeze-resistant and may also be stored with food in the freezer. Due to the robustness of the Bio-Compound, the reusable containers are also break-proof and particularly stable. This offers advantages, especially during transport. The reusable bowls, reusable boxes, plates, menu plates, cups, and bowls also have an antibacterial effect, are biobased, and food-compliant. The practical use for takeaway of cups, bowls with delicious curry, hearty stews, juicy steaks, pasta, Asian food, kale, or creamy desserts and desserts is no problem! Bowls and bowls are ideal for salads and unpackaged foods such as muesli, cereals, or nuts. Together with the transparent or gray-transparent lid, the content remains fresh and clearly visible. The reusable cups are ideal for hearty soups and stews, the menu boxes separate dishes with their compartments and prevent them from running together.

What reusable products do we offer?

All products except for the lids are made with a Bio-Compound of natural fibers and bio-plastics. The special material formulation was developed as part of a project funded by the Federal Ministry for Economic Affairs and Energy.

Production steps in the production of Bio-Compound

- Natural fibers serve as a sustainable filler in the production of Bio-Compound. The lignocellulose comes as an unused by-product from production processes and is sustainably reintroduced into the production cycle according to the “waste to value” principle.

- These processed natural fibers are combined with bio-plastics to form a composite. The more natural fibers used in this process, the more sustainable the product becomes.

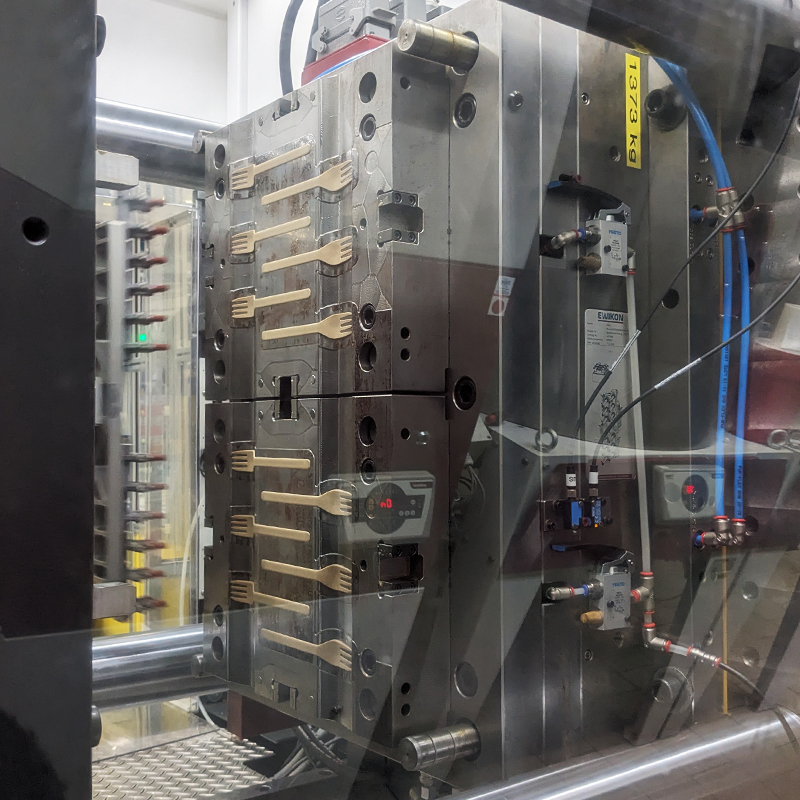

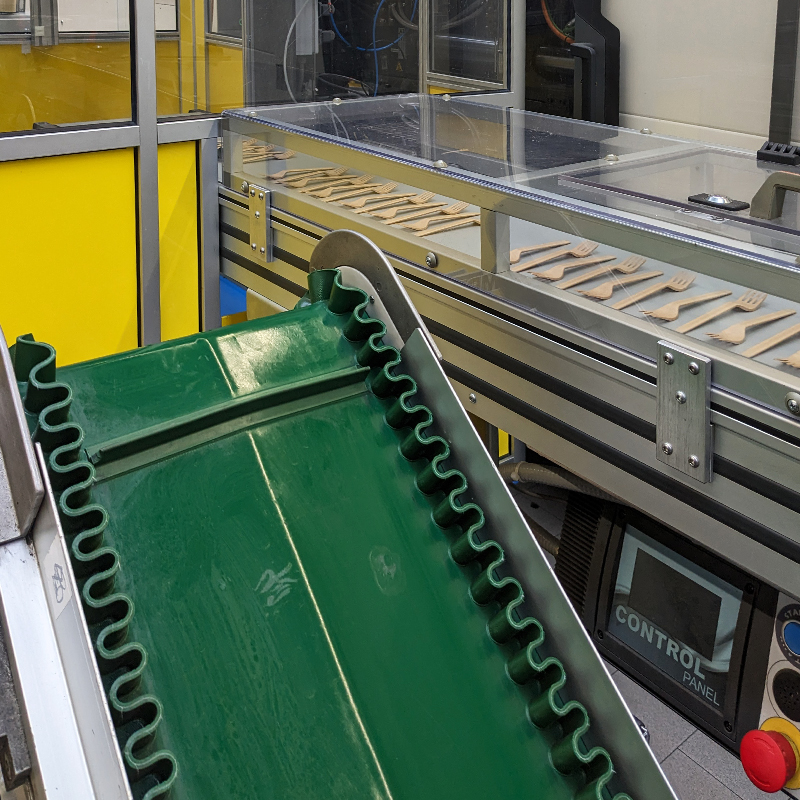

- The resulting composite is then heated in an injection molding machine and injected into a special mold under high pressure. When designing a product, attention is paid not only to the production-related requirements but also to ensuring that it fits comfortably in the hand and leaves a pleasant mouthfeel. The production process is completed after cooling.

- Finished. The reusable plates, bowls, burger boxes, cups, and cutlery are ready for transport and look forward to being used in gastronomy, canteens, at events, or other areas in the food service.

Advantages of reusable products

Since the Bio-Compound is made from renewable, plant-based raw materials, it contributes to the conservation of non-renewable resources. The use of bio-plastics also reduces the use of conventional plastic. This is particularly welcomed by end consumers, as more and more people integrate sustainability into their everyday lives or make other individual contributions to environmental protection. To reduce the CO2 footprint, modern production facilities and short transport routes are increasingly being used (manufactured in Germany). The best thing about Bio-Compound is the durability of the material. They make the products not only sustainable but also economically attractive. You can find the entire range of reusable packaging in our offer.